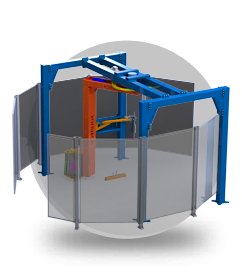

SCRTA SERIES

This automatic rotary tower system can be inserted into an existing conveyor line, or installed as a standalone system. The operator simply has to bring the pallet load to the conveyor or fed by pallet handling conveyor system. The pallet load is indexed automatically, the load is wrapped and the film gets cut and wiped at the end of the cycle without any operators intervention.

Should you be looking for certain options, be sure to inform us. If you are looking for something not included in our current list, we will design it to meet your needs.

VIDEO WITH INCYCLE TOP SHEET DISPENSER:

SRTA SERIES

These rotary tower automatic stretch wrappers provide ease of operation by allowing the operator to start the system without getting off the forklift. The system automatically attaches the stretch film at the beginning of the cycle and cuts and wipes the film at the end of the cycle lowering the risk of injury for the operator and optimizing the wrapping cycle time. Should you be looking for certain options, be sure to inform us. If you are looking for something not included in our current list, we will design it to meet your needs.

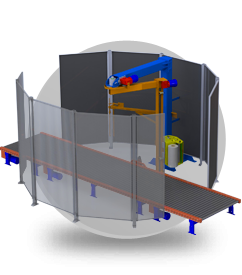

SCTA

The Automatic SCTA series includes 5′ infeed and 5′ outfeed conveyors. This fully automated systems requires simply loading and unloading of conveyors with pallet loads, the complete wrapping cycle is done automatically.

Should you be looking for certain options, be sure to inform us. If you are looking for something not included in our current list, we will design it to meet your needs.

SHPA

This series features automatic turntable high profile stretch wrappers providing a real user-friendly operation by allowing the operator to start the system from the forklift. The system automatically attaches the stretch film at the beginning of the cycle and cuts and wipes the film at the end of the cycle increasing ergonomics, profitability and decreasing the risk of work related injuries.

Should you be looking for certain options, be sure to inform us. If you are looking for a new application, we will design it to meet your needs.

SLPA SERIE

These turntable low profile automatic stretch wrappers provide ease of operation by allowing the operator to start the system without getting off the forklift. The system automatically attaches the stretch film at the beginning of the cycle and cuts and wipes the film at the end of the cycle increasing ergonomics, return of investment and safetiness in the work space.

Should you be looking for certain options, be sure to inform us. If you are looking for a new application not included in our current list, we will design it to meet your needs.

SRT

Ideal for unstable or overweight pallet loads, the SRT series uses a rotary tower attached to a 20” powered pre stretch carriage which rotates around a stationary pallet load on the floor. In addition to maximizing film usage with the pre-stretch carriage, these machines are ideal for situations that require frequent floor cleaning since they don’t have a large foot print and there are no components on the floor.

SHP

All our SHP high profile stretch wrapping machines are designed to be loaded by forklift only. Compared with a manually wrapped pallet, the SLP SHP models allow a desirable return on investment by optimizing operator labor and maximizing the use of stretch film. The SHP machine wraps load after load safely and consistently. Stretching the film through a machine operation provides a more secure load at an economical cost.

These models are equipped with a pre stretch film carriage installed on the side of the machine to offer the best working ergonomics for the operators. A safety switch installed under the carriage stops the carriage should anything be located in its way.

Should you be looking for certain options, be sure to inform us. If you are looking for something not included in our current list, we will design it to meet your needs.

SLP

Our semi-automatic turntable stretch wrappers have been designed to meet specific customer needs in terms of day to day packaging requirements. Whatever your challenge may be in terms of packaging machinery, Solutech will provide you with an excellent solution for your investment, starting with safety, reliability, cost effectiveness and efficiency.

Compared with a manually wrapped pallet, the SLP models allow a desirable return on investment by optimizing operator labor and maximizing the use of stretch film. The SLP machine wraps load after load safely and consistently. Stretching the film through a machine operation provides a more secure load at an economical cost.

Most of these models are equipped with a pre stretch film carriage installed on the side of the machine to offer the best working ergonomics for the operators. A safety switch installed under the carriage stops the carriage should anything be located in its way.

INTELLI-WRAP

Semi-Automatic portable stretch wrapping system

To wrap 15-20 loads per hour, this machine is ideal for distribution centers.

- Perfect for distribution centers, wrapping pallet to pallet, avoiding double load handling.

- Ideal to wrap oversize loads, avoiding high costs of custom machines.

- Operates with batteries , 12 hours of autonomy, for 8 hours of charging time.

With it’s capacity to Pre-stretch the film, this machine offers a 20’’ film carriage, including several advantages:

- Considerable film costs reduction;

- Better pallet load retention for a safe shipment;

- Provide a lesser environmental foot print than manually wrapped loads

- Solutech offers 25 years experiences, in the manufacturing of stretch wrappers of all kinds, palletizers and material handling equipment.